As early as 1946, Dr. Georg Schaeffler (Georg Schaeffler) and his brother Wilhelm (Wilhelm) co-Launched Schaeffler AG, and in 1949 proved the significance of breaking throughout the pondering body. At the moment, his analysis and growth of the needle roller and cage assembly triggered An important breakthrough in the appliance of needle roller bearings in the commercial area and stuffed the gap On this subject.

For the reason that needle rollers will not be retained by mechanical suggests, they are secured for transportation and fitting by the use of a Exclusive grease (DIN 51825–K1/2K–thirty). Even so, this does not have enough lengthy-time period lubrication capability. Relubrication is therefore encouraged immediately after fitting.

Application examples contain the use of lead in solder, or as an ingredient in metallic composite bearings, and the use of PBB as being a flame retardant. The substances also usually occur in metallic alloys.

Do away with removing gears and dismantling drives for diminished replacement time, upkeep fees and output loss.

Decayed subsoil and Filth, generally in the shape of leaves, accumulates in swimming pools more than the winter months, which can be tough to eliminate. Radial ball bearings from igus® grant pool cleaners a gentle and effective underwater operation.

INA Stud form track roller PWKR comprise thick-walled outer rings which has a profiled lateral surface area, good segment roller studs that has a correcting thread

Total complement drawn cup needle roller bearings with open up finishes have the utmost amount of needle rollers and as a consequence present extremely superior load-carrying ability inside a extremely small design envelope. However, their use at higher speeds is restricted.

Due to an improved surface area good quality, the load rankings of X-lifestyle needle roller bearings are amplified even further more. The dynamic load score could be greater by thirteen % when compared with the previous needle roller bearings. The considerably improved load rankings bring about better-functionality bearings with an extended company existence, lessened lubricant load, diminished friction and lower bearing temperatures.

INA crossed roller bearings SX are bearings for top precision programs, whose key Proportions correspond for the ISO dimension sequence eighteen with extremely smaller section height in accordance with DIN 616. They comprise outer rings, interior rings, rolling el

They may have significant load carrying ability, are suited to substantial speeds and so are notably very easy to in shape. In case the raceways are developed to large geometrical accuracy, bearing arrangements with large runout accuracy can be achieved.

Drawn-cup roller clutches give quite exact indexing, because the individual spring loading on the needle rollers assures constant Call NSK bearing between the shaft, needle rollers and ramps.

All have a hex socket head. Lubrication holes are located over the radial diameter on the stud stem and during the threaded stop with the stud, unless in any other case observed. End seals block contaminants. Highest temperature is 250F. Mounting nut not involved.

Carter's State-of-the-art layout self-lubricating sleeve bearing gives constant, trustworthy lubrication for that lifetime of the unit. Mainly because there aren't any inside relocating components, Neverlube™ bearings give difficulty-free of charge operation in lots of purposes, including situations wherever the tools is topic to frequent wash downs.

Immense and fluctuating hundreds. Speeds that range from exceptionally lower in primary shafts to swift acceleration and deceleration in gearboxes. Lubrication problems, together with international and procedure generated contamination.

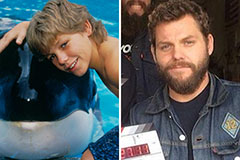

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now!